The Department of Energy’s SunShot Initiative funds cutting-edge science that helps dramatically reduce the cost of solar energy. Drawn from diverse inspiration in the optical and medical fields, and featuring one with new uses for sound waves, these newly announced SunShot research and development projects may hold the key to low-cost solar energy.

Energy Department-supported scientists have already devised some amazing uses for sound waves. You can make fuel from algae or use them as a refrigerant, and now one project is looking to use acoustic waves to make silicon wafers for solar photovoltaics (PV). In the recently announced project at Arizona State University, researchers address the problem of kerfing by using sound waves. Like sawdust, kerfing is the byproduct of sawing silicon wafers that results in a lot of expensive, wasted silicon. In this project, researchers are hoping to pop off wafers by using a stressor layer and sound.

Primary investigator Mariana Bertoni will use sound-assisted spalling to peel a wafer from a silicon block, doubling the yield of a silicon ingot and eliminating traditional abrasive slurries, wires, and multiple cleaning steps traditionally used to manufacture silicon wafers. Her team will precisely engineer the stress applied to layers in order to spall thicker wafers and control the fracture front to ensure high-quality surfaces. This technology, combined with state-of-the-art manufacturing, has the potential to achieve highly efficient, lightweight, and inexpensive solar modules at prices far below the current industry standard.

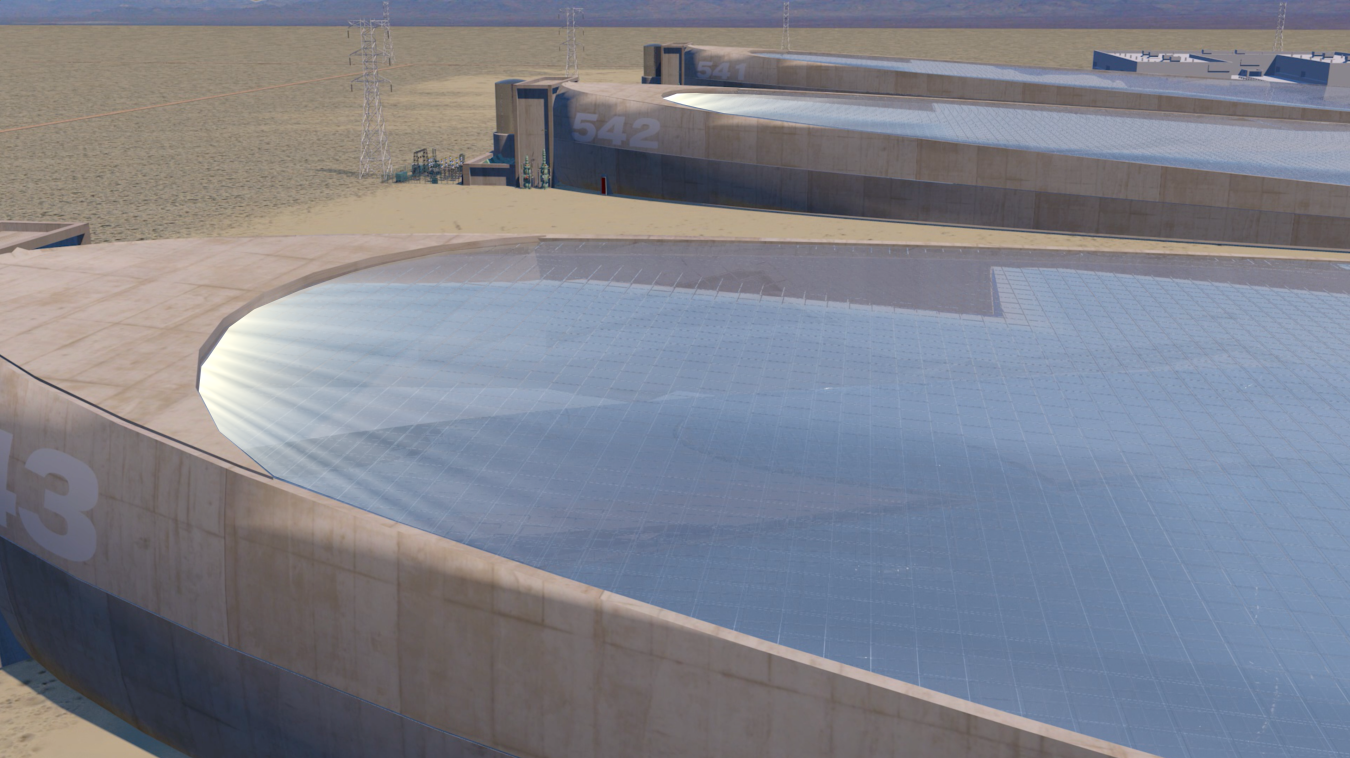

Beyond sound waves, technologies behind the liquid crystal displays (LCD) that are used in televisions and computer screens are now being used to collect more sunlight in concentrating solar power (CSP) collectors. In a CSP plant, solar collectors use reflective surfaces to concentrate sunlight onto a smaller surface, called a receiver, where it is absorbed and converted into heat. Most existing CSP plants use parabolic troughs or heliostat collectors that are grouped into a solar field. The solar field represents the largest cost within a CSP plant – roughly 40% of the total plant cost.

The project led by Agira uses technologies developed for LCDs to make a flat surface behave like a curved surface, bending and directing light to a desired area. The company uses turning films, thin layers of material that can refract light and can be made with low-cost materials and industry-standard manufacturing methods. In LCDs, these films turn the backlight from the lamps to create a uniform–and bright–light source to go through the liquid crystal pixels. In a CSP collector, it will bend light toward a receiver. As a result, the company believes it can manufacture solar collectors at a low cost.

Another project tackling the high cost of solar collectors uses microfluidics to direct light less expensively than current mirrors. Microfluidic devices and processes manipulate tiny amounts of fluids, in the nanoliters range. These devices have been used in medical diagnostics to test small samples of fluids for diseases at a low cost and in a short timeframe. The project by Giant Leap Technologies will use microfluidics to bend light using micron-scale capillaries containing a refractive fluid distributed within a transparent solid. The physical distribution of the fluid within the capillaries allows light to be steered to a solar receiver, where it can be captured and turned into energy.

The SunShot Initiative is looking far and wide for the next innovations that will drive the solar industry to even lower cost solar generation. These ideas often have high technical risk and lack funding for demonstration projects. By supporting these efforts, SunShot is playing a critical role in advancing early-stage research that demonstrates the potential for expanded work in emerging areas of solar research. Explore more of the latest innovations in PV and CSP.